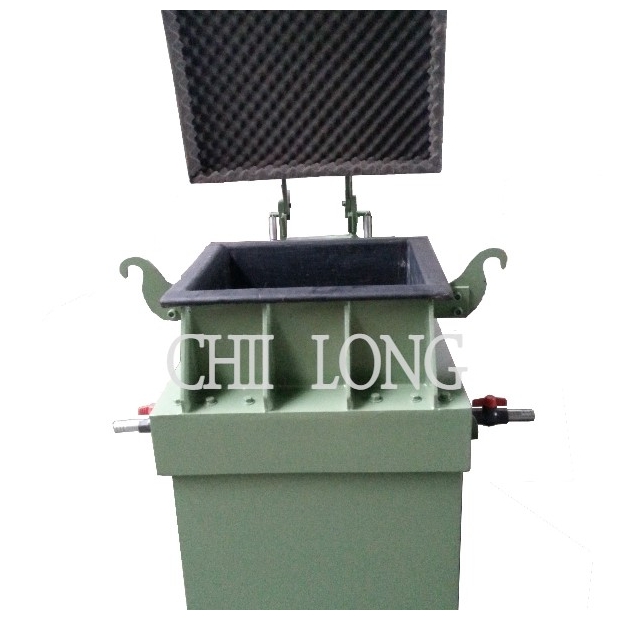

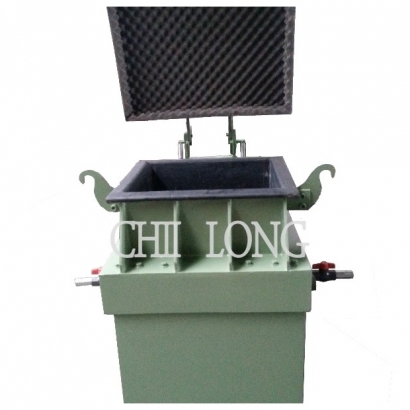

Noise-Reduction Flip-Top Vibratory Finishing Machine - VB-100BC

3D Vibratory Finishing Machine

Features

-

Three-Dimensional Motion: The machine vibrates in three directions, allowing full interaction between the workpieces and media, ensuring uniform finishing on all surfaces.

-

High Efficiency: Shortens finishing time compared to traditional vibratory machines, improving production efficiency.

-

Suitable for Large and Long Workpieces: Cone or bow-shaped design increases tank capacity and facilitates flipping and separating long or large parts.

-

Noise Reduction: Some models are equipped with soundproof covers or flip-top lids to reduce operational noise.

-

User-Friendly Operation: Ergonomic design makes loading and unloading easy, reducing labor time.

Applications

-

Ideal for deburring, chamfering, polishing, and removing black films.

-

Suitable for metals (aluminum, steel, stainless steel, copper) and non-metals (plastic, ceramic).

-

Commonly used in hardware, electronic components, automotive parts, medical devices, utensils, and tools industries.

Options and Notes

-

Compatible with various abrasive media (alumina stones, ceramic stones, plastic stones) and polishing compounds.

-

Optional features include variable frequency drives, digital timers, or automatic discharge systems

Applications

-

Designed to reduce noise generated during the vibratory finishing process.

-

Machine dimensions can be adjusted according to size; operation is simple and user-friendly.

Note

-

Due to variations in mechanical design, the actual appearance is subject to the physical machine.