⚙️High-Speed Centrifugal Finishing Machine⚙️

-

Read More

High-Speed Centrifugal Grinding Machine-SHOK-3600

High-Speed Centrifugal Grinding Machine-SHOK-3600High-Speed Centrifugal Grinding Machine-SHOK-3600

Features:

Long service life, high mechanical efficiency, strong cutting force, and uniform grinding.

Time- and labor-saving, easy to operate, low noise, suitable for continuous day-and-night operation.

Applications:

Stepless and multi-speed rotation control.

Digital timer control switch.

Barrel positioning control switch (available on models OK-3600 and OK-3200). -

Read More

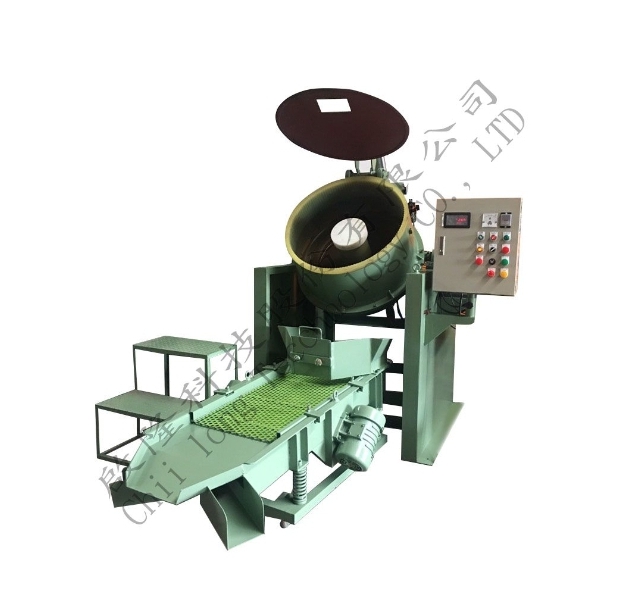

Automatic Tiltable High-Speed Grinding & Sorting Machine – OK-350+S1

Automatic Tiltable High-Speed Grinding & Sorting Machine – OK-350+S1Automatic Tiltable High-Speed Grinding & Sorting Machine – OK-350+S1

High-Efficiency Grinding & Sorting

Fast Grinding: The centrifugal rotation action allows grinding time to be approximately 10 times faster than traditional vibratory finishing machines, reducing processing time by half (STOK series feature). The fixed trough and rotating plate design generates strong mechanical energy, achieving complete mixing of workpieces and media for uniform and visually appealing surface finishing.

Automatic Sorting (S1 System): The S1 system provides automatic sorting of workpieces and grinding media after processing, reducing manual labor and improving efficiency. Separated media can be returned via conveyor for reuse, while workpieces are sent to the discharge outlet for subsequent processes. -

Read More

Automatic Tiltable High-Speed Centrifugal Grinding Machine (Hydraulic Cylinder Device) – OK-350OC

Automatic Tiltable High-Speed Centrifugal Grinding Machine (Hydraulic Cylinder Device) – OK-350OCAutomatic Tiltable High-Speed Centrifugal Grinding Machine (Hydraulic Cylinder Device) – OK-350OC

Automatic Tiltable High-Speed Centrifugal Grinding Machine (Hydraulic Cylinder Device) – OK-350OC

Features

High-Speed Grinding: Centrifugal rotation action allows grinding time approximately 10 times faster than traditional machines.

Efficient Deburring & Surface Treatment: Suitable for chamfering, oil removal, oxide layer removal, and polishing to enhance workpiece surface quality.

Automated Digital Control: Digital control system with user-friendly design (optional for certain models).

Fully Automated Operation: No manual intervention required during the grinding process, reducing labor costs.

Tiltable Trough Design: The trough can tilt and automatically discharge material, facilitating sorting and subsequent processing.

Multi-Functional Processing: Performs chamfering, deburring, oil removal, oxide removal, and surface polishing.

Automatic Sorting: Post-grinding separation of workpieces and media for improved operational efficiency. -

Read More

High-Speed Centrifugal Grinding Machine – STOK

High-Speed Centrifugal Grinding Machine – STOKHigh-Speed Centrifugal Grinding Machine – STOK

High-Speed Centrifugal Grinding Machine – STOK

Features

High-Speed Grinding: Grinding time is reduced by approximately 50% compared to traditional vibratory finishing machines.

Powerful Processing: The fixed trough and rotating plate design create mechanical energy dynamics between the workpieces and grinding media, achieving complete mixing and maximum mutual grinding.

Uniform Results: Achieves uniform and aesthetically pleasing surface finishes in a short processing time.

Applications

Suitable for small workpieces.

Powerful grinding capability for deburring, chamfering, and oxide layer removal. -

Read More

Tiltable Centrifugal Grinding Machine – OK-150

Tiltable Centrifugal Grinding Machine – OK-150Tiltable Centrifugal Grinding Machine – OK-150

Tiltable Centrifugal Grinding Machine – OK-150

Features

High-Speed Grinding: Centrifugal rotation action allows grinding time approximately 10 times faster than traditional machines.

Efficient Deburring & Surface Treatment: Suitable for chamfering, oil removal, oxide layer removal, and polishing.

Multi-Functional Processing: Performs chamfering, deburring, oil removal, oxide removal, and surface polishing to enhance workpiece surface quality. -

Read More

Tiltable Centrifugal Grinding Machine-OK-50

Tiltable Centrifugal Grinding Machine-OK-50Tiltable Centrifugal Grinding Machine-OK-50

Tiltable Centrifugal Grinding Machine – OK-50

Features

High-Speed Grinding: Centrifugal rotation action allows grinding time approximately 10 times faster than traditional machines.

Efficient Deburring & Surface Treatment: Suitable for chamfering, oil removal, oxide layer removal, and polishing.

Digital Control: User-friendly design (optional for certain models).

Fully Automated Operation: No manual intervention required, saving labor.

Tiltable Trough Design: Drum can tilt with fully automatic discharge for easy loading/unloading and subsequent processing.

Multi-Functional Processing: Performs chamfering, deburring, oil removal, oxide removal, and surface polishing. -

Read More

High-Speed Centrifugal Grinding Machine – SHOK-3800

High-Speed Centrifugal Grinding Machine – SHOK-3800High-Speed Centrifugal Grinding Machine – SHOK-3800

High-Speed Centrifugal Grinding Machine – SHOK-3800

Features

Digital Control: Equipped with a digital control switch including stepless speed adjustment for flexible and easy operation.

Power-Off Memory (Optional): Remembers previous settings and resumes operation after power failure, enhancing user convenience.

Automatic Positioning (Optional): Grinding drum can be equipped with infrared automatic positioning system for improved grinding accuracy.

Automatic Sorting & Cleaning: After grinding, the machine automatically separates grinding media and workpieces, with cleaning function to reduce manual handling and improve efficiency. -

Read More

High-Speed Centrifugal Grinding Machine – SHOK-3200

High-Speed Centrifugal Grinding Machine – SHOK-3200High-Speed Centrifugal Grinding Machine – SHOK-3200

High-Speed Centrifugal Grinding Machine – SHOK-3200

Features

Digital Control: Equipped with a digital control switch including stepless speed adjustment for flexible operation.

Automatic Sorting & Cleaning: After grinding, the machine automatically separates grinding media and workpieces, with a cleaning function to reduce manual labor and improve efficiency.

Efficient Grinding: High-speed centrifugal design provides strong cutting power for deburring, chamfering, oxide removal, and polishing operations.

Long Service Life & Low Noise: Constructed with durable materials for stable operation, suitable for continuous day-and-night use, with low operational noise.

Optional Features: Power-off memory, automatic positioning (infrared), PLC control, enhancing precision and automation.

Applications

Suitable for small metal components, hardware, electronic parts, and medical device components requiring high-precision surface finishing.

Compatible with various materials: metals (aluminum, copper, stainless steel) and non-metals (plastics, ceramics). -

Read More

High-Speed Centrifugal Grinding Machine – SHOK-1000

High-Speed Centrifugal Grinding Machine – SHOK-1000High-Speed Centrifugal Grinding Machine – SHOK-1000

High-Speed Centrifugal Grinding Machine – SHOK-1000

Features

Long Service Life & High Mechanical Efficiency: Durable design suitable for industrial continuous use.

Strong Cutting & Uniform Grinding: Ideal for small components and labor-intensive workpieces, ensuring consistent processing quality.

Time-Saving & Easy Operation: No dedicated personnel required; low noise, suitable for continuous day-and-night operation.

Maintains Workpiece Shape: High-speed centrifugal design with premium grinding materials prevents deformation.

High-Quality Materials: Uses PU produced by DuPont (USA) for durability and efficiency.

Digital VFD (Variable Frequency Drive): Adjustable grinding speed to accommodate different materials and processing needs.

Applications

Small components, precision hardware, electronic parts, medical device components, etc.

Suitable for surface finishing and precision grinding of metals (aluminum, copper, stainless steel) and non-metals (plastics, ceramics).