⚙️Vibratory Finishing Machine⚙️

-

Read More

Vibratory Finishing Machine VB-A Series

Vibratory Finishing Machine VB-A SeriesVibratory Finishing Machine VB-A Series

The Automatic Screening Vibratory Finishing Machine is suitable for workpieces prone to deformation or impact marks, as well as for grinding or sorting operations. The upper perimeter of the machine features a spiral-shaped inclined channel, where the mixture of workpieces and media flows forward in a helical motion toward the sorting area during the selection process. -

Read More

3D Vibratory Finishing Machine-VB-B

3D Vibratory Finishing Machine-VB-B3D Vibratory Finishing Machine-VB-B

振動研磨機

Vibratory Finishing Machine

特點 (Features)

機台槽內批覆 PU,具 耐酸、耐磨特性,提升耐用性。

The machine bowl is lined with PU (polyurethane), offering acid and wear resistance for long service life.

槽內底部 U 型設計,使工件在研磨過程中翻滾流動,摩擦壓力更大、研磨效果更佳。

The U-shaped bowl bottom enhances tumbling movement and pressure, resulting in stronger grinding and polishing performance.

無自動篩選功能,需人工取料,亦可 搭配篩選機 使用以提升效率。

No automatic separation function; manual unloading is required, but can be paired with a separator for higher efficiency. -

Read More

Workpiece Isolation Fixture – Movable Type

Workpiece Isolation Fixture – Movable TypeWorkpiece Isolation Fixture – Movable Type

Workpiece Isolation Fixture – Movable Type

Application:

A movable isolation fixture designed for grinding and polishing processes. Each workpiece is placed into a separate compartment to prevent collision, scratches, or damage during processing.

Features:

Movable design for easy assembly and operation.

Effectively prevents workpieces from colliding with each other.

Ensures consistency and high-quality surface finishing.

Custom designs can be provided according to customer requirements. -

Read More

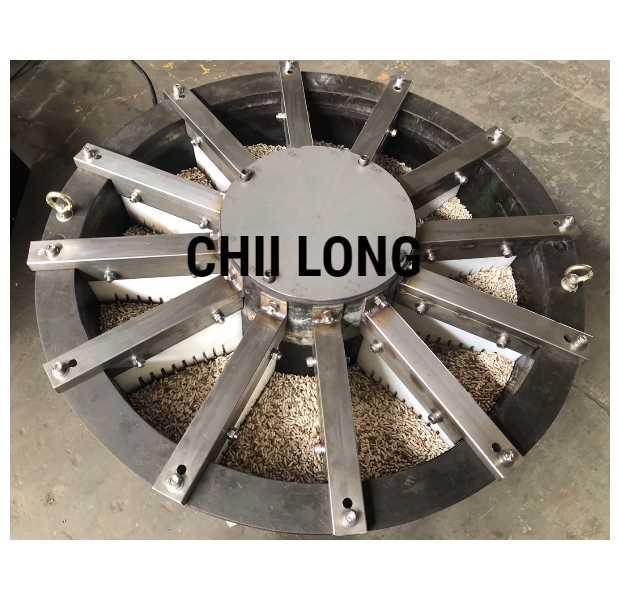

Vibratory Finishing Machine – Workpiece Isolation Fixture (Fixed Type)

Vibratory Finishing Machine – Workpiece Isolation Fixture (Fixed Type)Vibratory Finishing Machine – Workpiece Isolation Fixture (Fixed Type)

Vibratory Finishing Machine – Workpiece Isolation Fixture (Fixed Type)

Application:

A customized fixed-type isolation fixture designed according to customer requirements. It is especially suitable for small and delicate workpieces that are prone to damage from collisions during the grinding or polishing process.

Features:

Fixed-type structure with 12 individual compartments.

Ideal for small workpieces requiring protection against impact.

The rubber plate at the compartment bottom can be cut into long slots according to product characteristics, allowing media and workpieces to tumble more effectively, thereby improving grinding efficiency.

Custom designs available to meet specific customer requirements. -

Read More

Tiltable Vibratory Finishing Machine - VBT-50BB

Tiltable Vibratory Finishing Machine - VBT-50BBTiltable Vibratory Finishing Machine - VBT-50BB

Tiltable Vibratory Finishing Machine - VBT-50BB

Features:

After finishing, the machine can tilt to automatically discharge the workpieces, saving labor and time.

The machine can tilt at any angle, making unloading more convenient.

Fully automatic tilting design eliminates the need for manual part removal.

Equipped with a digital inverter to adjust rotation speed, ensuring the required finishing quality is achieved.

Applications:

Suitable for small-sized workpieces.

Applicable for polishing, deburring, and chamfering operations. -

Read More

Vibratory Alignment Machine - VB-P

Vibratory Alignment Machine - VB-PVibratory Alignment Machine - VB-P

Vibratory Alignment Machine - VB-P

Features:

Utilizes vibratory motion to automatically align and arrange workpieces.

Significantly reduces labor time and cost for manual alignment.

Ideal for workpiece arrangement before subsequent processing or inspection.

Customizable alignment slots according to workpiece size and shape.

Applications:

Specially designed for automatic alignment of small workpieces.

Suitable for workpiece arrangement before polishing or inspection.

Can be integrated with vibratory finishing machines and other processes to improve overall efficiency. -

Read More

Soundproof Tilting-Cover Vibratory Finishing Machine - VB-CC

Soundproof Tilting-Cover Vibratory Finishing Machine - VB-CCSoundproof Tilting-Cover Vibratory Finishing Machine - VB-CC

Soundproof Tilting-Cover Vibratory Finishing Machine - VB-CC

Application:

Designed to reduce noise generated during the vibratory finishing process, creating a quieter and more comfortable working environment.

Features:

Soundproof tilting-cover design effectively minimizes noise during operation.

Can be designed to fit various sizes of vibratory finishing machines.

Easy to operate with convenient cover opening and closing.

Note:

Appearance may vary depending on the machine model; actual design shall prevail. -

Read More

Vibratory Grinding Machine – VB-E Type

Vibratory Grinding Machine – VB-E TypeVibratory Grinding Machine – VB-E Type

Vibratory Grinding Machine – VB-E Type

Features

Central Cone Design: Enlarged opening increases grinding volume, suitable for large and long-shaped workpieces.

Versatile Surface Treatment: Deburring, chamfering, black oxide removal, polishing.

Applications

Large workpieces, long components, hand tools, etc.

Suitable for hardware, automotive parts, electronic components, and other applications requiring high-volume grinding. -

Read More

Vibratory Grinding Machine – VB-C Type

Vibratory Grinding Machine – VB-C TypeVibratory Grinding Machine – VB-C Type

Features

Compact footprint with large capacity, easy to operate: Space-saving design, convenient operation and maintenance.

High-frequency vibration with multi-directional regular motion: Ensures uniform grinding and improves processing efficiency.

Strong cutting force and uniform grinding: Suitable for precision processing of various materials.

Suitable for large workpieces: Such as long shafts or disc-shaped components. -

Read More

3D Vibratory Finishing Machine - VB-750BC

3D Vibratory Finishing Machine - VB-750BC3D Vibratory Finishing Machine - VB-750BC

Features

Compact footprint with large capacity

Suitable for medium to large workpieces, saving factory space.

High-frequency vibration with multi-directional motion

Improves finishing efficiency and ensures uniform surface treatment.

Strong cutting force and uniform grinding

Ideal for deburring, chamfering, and surface polishing.

Suitable for large workpieces

Such as long shafts, disc-shaped workpieces, or complex-shaped parts.

Dust-proof and sound-proof cover

Provides a clean and safe working environment, reducing dust and noise pollution. -

Read More

Manual Eco-Friendly Flip-Top Vibratory Finishing Machine - VB-25AB

Manual Eco-Friendly Flip-Top Vibratory Finishing Machine - VB-25ABManual Eco-Friendly Flip-Top Vibratory Finishing Machine - VB-25AB

Applications

Reduces operational noise generated during finishing processes.

Easy to operate, suitable for small to medium-sized workpieces. -

Read More

Automatic Eco-Friendly Flip-Top Vibratory Finishing Machine - VB-50AB

Automatic Eco-Friendly Flip-Top Vibratory Finishing Machine - VB-50ABAutomatic Eco-Friendly Flip-Top Vibratory Finishing Machine - VB-50AB

Automatic Eco-Friendly Flip-Top Vibratory Finishing Machine - VB-50AB

Applications

Reduces operational noise generated during finishing processes.

Easy to operate, suitable for small to medium-sized workpieces.

Note

The actual machine appearance may vary; refer to the physical machine for the exact design.