⚙️sandblaster⚙️

-

Read More

Carborundum – Silicon Carbide Abrasive

Carborundum – Silicon Carbide AbrasiveCarborundum – Silicon Carbide Abrasive

Carborundum – Silicon Carbide Abrasive

Material: Silicon Carbide (SiC)

Applications: Similar to alumina abrasives

Rust removal, paint stripping, mold cleaning

Can be manufactured into sandpaper, abrasive cloth, grinding stones, etc.

Key Features:

Extremely high hardness, second only to diamond

Strong cutting and grinding force, effective for tough surface coatings and residues

Excellent heat resistance and thermal conductivity, suitable for harsh conditions

Widely used for processing metals, ceramics, glass, and stone

外觀呈現:多角形

顏色:黑色(25kg/袋) -

Read More

Steel Ball

Steel BallSteel Ball

Steel Ball

Appearance: Spherical granules

Packaging: 30 KG/bag

Applications:

Filter media for filtration systems

Sandblasting and mold cleaning

Key Features:

Spherical shape ensures uniform stress distribution and excellent flow properties, ideal for filtration use.

Effective in removing residues, oxidation layers, or coatings from mold surfaces during sandblasting.

Reusable, offering cost efficiency. -

Read More

Stainless Steel Ball

Stainless Steel BallStainless Steel Ball

Stainless Steel Ball

Appearance: Spherical granules

Packaging: 30 KG/bag

Applications:

Surface roughening or deburring of aluminum and zinc castings

Surface finishing for stainless steel components

Cleaning or texturing of cement and stone surfaces

Key Features:

Made of stainless steel, offering excellent corrosion resistance and durability.

Spherical shape provides uniform impact distribution, enhancing processing efficiency.

Suitable for applications requiring surface roughening, deburring, or cleaning. -

Read More

White Aluminum Oxide

White Aluminum OxideWhite Aluminum Oxide

White Aluminum Oxide

Appearance: Angular granules

Packaging: 25 KG/bag

Applications:

Frosted surface finishing for polyester or acrylic crafts

Dental mold treatment

Sandblasting in precision casting and related applications

Key Features:

High hardness and excellent wear resistance, suitable for sandblasting and grinding

Angular particle shape ensures uniform frosting effects

Non-contaminating, ideal for industries requiring high cleanliness -

Read More

Aluminum Sand

Aluminum SandAluminum Sand

Aluminum Sand

Appearance: Angular granules

Packaging: 25 KG/bag

Applications:

Frosted surface finishing for polyester or acrylic crafts

Dental mold treatment

Sandblasting in precision casting and related applications

Key Features:

Hard and durable particles with excellent wear resistance

Produces a uniform frosted effect

Suitable for fine and delicate workpiece processing -

Read More

CERAMIC SAND

CERAMIC SANDCERAMIC SAND

Ceramic Sand

Appearance: Ring-shaped granules

Packaging: 25 KG/bag

Applications:

Sandblasting

Rust and paint removal

Carbon deposit cleaning

Can be used as a substitute for glass beads in sandblasting

Key Features:

Hard and durable with high wear resistance

Reusable, providing cost efficiency

Produces a uniform surface finish without damaging workpieces -

Read More

SILICA SAND

SILICA SANDSILICA SAND

Silica Sand

Appearance: Ring-shaped granules

Packaging: 25 KG/bag

Applications:

Rust, paint, and carbon deposit removal

Elimination of machining tool marks

Surface cleaning before anodizing and electroplating, improving adhesion

Stainless steel weld seam cleaning and scratch removal

Key Features:

Uniform particle size with moderate cutting force

Effectively cleans workpiece surfaces and enhances coating adhesion

Suitable for metal finishing and surface pretreatment -

Read More

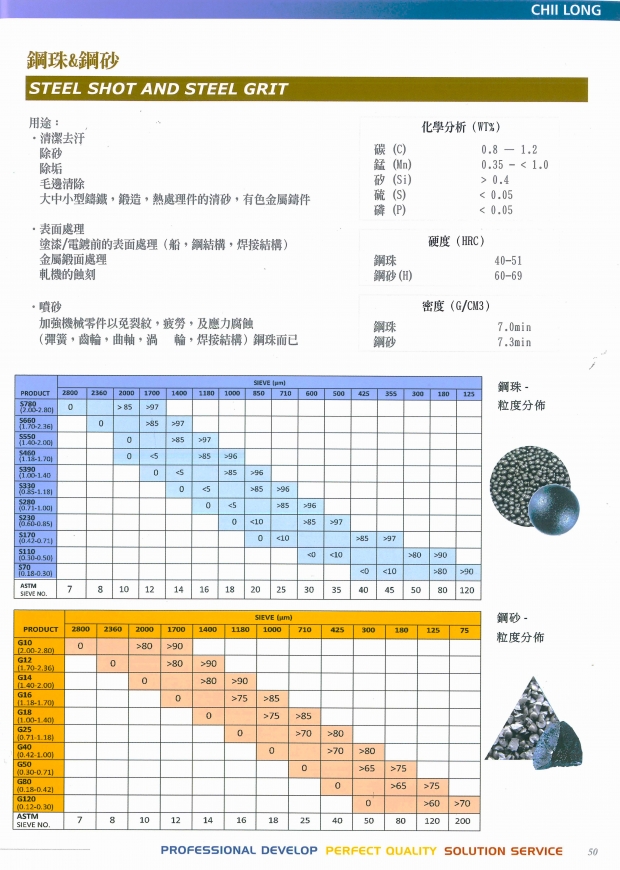

STEEL GRIT

STEEL GRITSTEEL GRIT

Steel Grit

Appearance: Angular granules

Applications:

Cleaning & Descaling

Removal of sand, scale, and burrs

Cleaning of small to large cast iron, forged parts, and heat-treated components

Non-ferrous metal casting cleaning

Surface Preparation

Pre-painting and pre-plating surface treatment (ships, steel structures, welded structures)

Surface finishing of forged metals

Rolling mill etching

Shot Blasting

Enhances mechanical parts to resist cracks, fatigue, and stress corrosion

Applicable to springs, gears, crankshafts, turbines, welded structures -

Read More

Enclosed Sandblasting Machine-Standard Model HSB-BA101-HSB-BA101

Enclosed Sandblasting Machine-Standard Model HSB-BA101-HSB-BA101Enclosed Sandblasting Machine-Standard Model HSB-BA101-HSB-BA101

“Clean, Precise, and Efficient Surface Finishing” -

Read More

Automatic Rotary Drum Sandblasting Machine

Automatic Rotary Drum Sandblasting MachineAutomatic Rotary Drum Sandblasting Machine

Automatic Rotary Drum Sandblasting Machine

Applications

Designed for mass processing of small workpieces, either in manual or automatic blasting mode.

Typical applications include:

Bakelite components

Screws and fasteners

Acrylic products

Plastic parts, sleeves, and similar small items

Optional Features

Rubber-Coated Drum: Recommended for workpieces that are prone to collision damage.

Oscillating Spray Gun System: Expands blasting coverage area and significantly improves efficiency.

Variable Frequency Drive (VFD): Allows adjustment of drum rotation speed to suit different workpiece requirements. -

Read More

Open-Type Sandblasting Machine – OB Series

Open-Type Sandblasting Machine – OB SeriesOpen-Type Sandblasting Machine – OB Series

Open-Type Sandblasting Machine – OB Series

Features

Simple and easy-to-learn operation

Stable blasting stream for consistent performance

Automatic nozzle anti-blocking design

High-speed processing capability

Durable sand control valve for long service life

Applications

Suitable for a wide range of industries and materials, including:

Stone, wood, and glass engraving

Aerospace industry (outdoor applications)

Shipbuilding and marine maintenance

Road and bridge repair

Steel plates and large workpieces sandblasting

Optional Accessories

Remote Control System: Enables remote sandblasting start/stop operation

Available in two types:

Pressure-Holding Type (manual pressure release)

Non-Pressure-Holding Type (automatic pressure release)

Remote switches available in:

Hand-held trigger type

Foot-pedal type -

Read More

Standard Conveyor-Type Automatic Sandblasting Machine

Standard Conveyor-Type Automatic Sandblasting MachineStandard Conveyor-Type Automatic Sandblasting Machine

Standard Conveyor-Type Automatic Sandblasting Machine

Application

Specially designed for the surface treatment of copper sheets, aluminum sheets, copper strips, and aluminum strips.

要不要我幫你補上 特點 (Features) 與 選用配備 (Optional Equipment) 的標準描述?

像是:

Continuous conveyor system for high efficiency

Uniform blasting coverage for consistent surface quality

Adjustable conveyor speed to meet different processing needs