Features:

The Automatic Screening Vibratory Finishing Machine is ideal for workpieces prone to deformation or impact marks, for both grinding and sorting operations. The upper perimeter of the machine is equipped with a spiral-shaped inclined channel, allowing the mixture of workpieces and media to flow forward in a helical motion toward the sorting area during operation.

Applications:

When processing workpieces susceptible to deformation or impact marks, the parts remain undamaged. The sorting area is equipped with a changeover gate and filter screen to separate media from the finished parts, enabling easy sorting and simple operation.

Model |

(Kg) Weight |

(Hp) Motor |

(Kw) Watt |

(mm) Width |

(P) Poles |

| VB-100 | 360 | 2 | 1.5 | ψ906*990H | 4P |

| VB-150 | 460 | 3 | 2.25 | ψ1045*1035H | 4P |

| VB-250 | 640 | 2 | 3.75 | ψ1200*1260H | 4P |

| VB-350 | 750 | 7.5 | 5.62 | ψ1340*1330H | 4P |

| VB-500 | 1070 | 10 | 7.5 | ψ1560*1560H | 4P |

| VB-750 | 1660 | 12 | 9 | ψ1730x1730H | 4P |

| VB-1000 | 2000 | 15 | 11.25 | ψ1850x1635H | 4P |

|

The above values are for reference only. Actual specifications may vary depending on the machine. |

|||||

The above values are for reference only. Actual specifications may vary depending on the machine.:

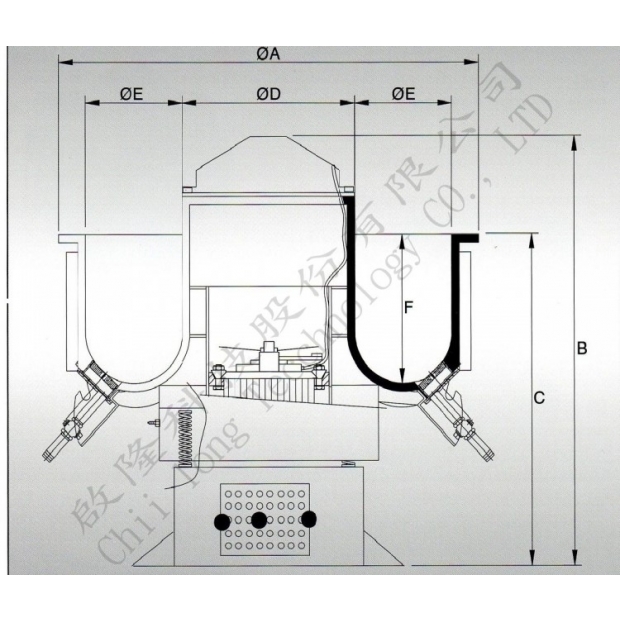

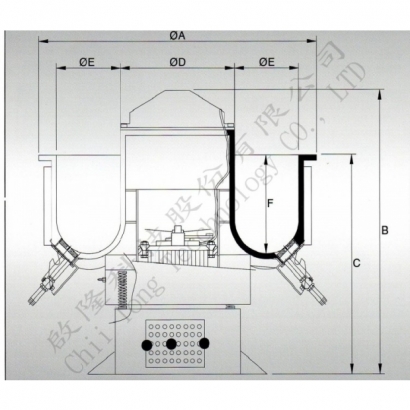

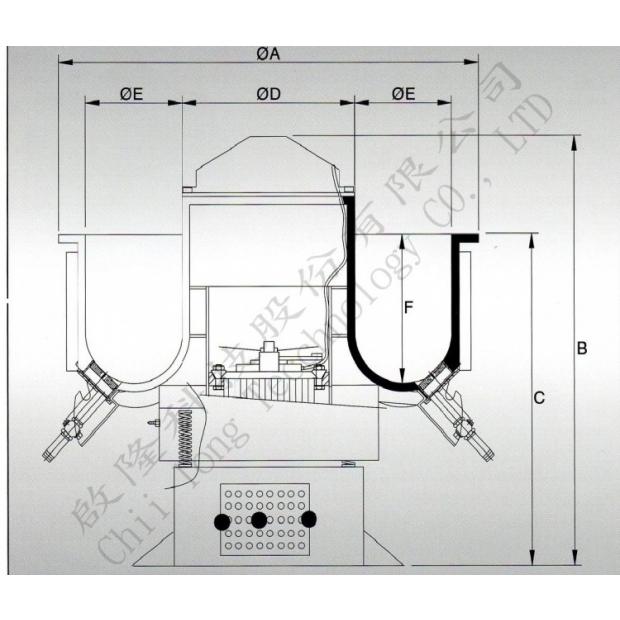

| size | A | B | C | D | E | F |

| 100 | 906 | 990 | 810 | 334 | 216 | 310 |

| 150 | 1045 | 1035 | 825 | 355 | 280 | 325 |

| 250 | 1200 | 1260 | 990 | 455 | 300 | 400 |

| 350 | 1340 | 1330 | 1025 | 550 | 320 | 450 |

| 500 | 1560 | 1360 | 1090 | 576 | 400 | 470 |

| 750 | 1730 | 1770 | 1400 | 770 | 410 | 550 |

| 1000 | 1880 | 1500 | 1300 | 810 | 445 | 670 |