Read More

White Aluminum Oxide

White Aluminum Oxide

White Aluminum Oxide

Read More

Aluminum Sand

Aluminum Sand

Aluminum Sand

Read More

CERAMIC SAND

Ceramic Sand

CERAMIC SAND

Read More

SILICA SAND

Silica Sand

SILICA SAND

Read More

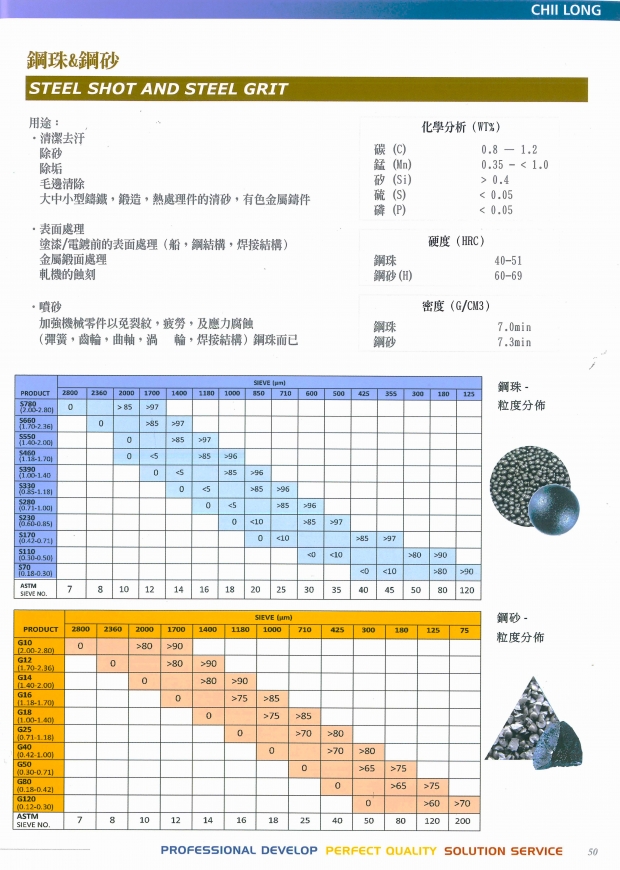

STEEL GRIT

Steel Grit

STEEL GRIT

Read More

Automatic Rotary Drum Sandblasting Machine

Automatic Rotary Drum Sandblasting Machine

Automatic Rotary Drum Sandblasting Machine

Read More

Open-Type Sandblasting Machine – OB Series

Open-Type Sandblasting Machine – OB Series

Open-Type Sandblasting Machine – OB Series

Read More

Standard Conveyor-Type Automatic Sandblasting Machine

Standard Conveyor-Type Automatic Sandblasting Machine

Standard Conveyor-Type Automatic Sandblasting Machine

Read More

Bead Grinding Machine – R

Bead Grinding Machine – R

Bead Grinding Machine – R

Read More

Customized Wheel Rim Grinding & Polishing Machine

Customized Wheel Rim Grinding & Polishing Machine

Customized Wheel Rim Grinding & Polishing Machine

Read More

Burr Removal & Surface Polishing-WP

Burr Removal & Surface Polishing

Burr Removal & Surface Polishing-WP

1 Page

2 Page

3 Page

4 Page

5 Page

6 Page

7 Page

8 Page

9 Page

10 Page

White Aluminum Oxide

White Aluminum Oxide Aluminum Sand

Aluminum Sand CERAMIC SAND

CERAMIC SAND SILICA SAND

SILICA SAND STEEL GRIT

STEEL GRIT Enclosed Sandblasting Machine-Standard Model HSB-BA101-HSB-BA101

Enclosed Sandblasting Machine-Standard Model HSB-BA101-HSB-BA101 Automatic Rotary Drum Sandblasting Machine

Automatic Rotary Drum Sandblasting Machine Open-Type Sandblasting Machine – OB Series

Open-Type Sandblasting Machine – OB Series Standard Conveyor-Type Automatic Sandblasting Machine

Standard Conveyor-Type Automatic Sandblasting Machine Bead Grinding Machine – R

Bead Grinding Machine – R Customized Wheel Rim Grinding & Polishing Machine

Customized Wheel Rim Grinding & Polishing Machine Burr Removal & Surface Polishing-WP

Burr Removal & Surface Polishing-WP